“Shipyard Production Management” is very relevance in the shipbuilding industry due to the evolution of the complexity of the equipments installed on board, mechanical components, electrical, electronic, automation, fluid, software, and a large list therefore the Management has become of the most importance and imply a big effort to keep under control.

This process will involved a large amounts of equipment, services, spare parts, documentation, workflow, reports, orders, team and the management of all these components requires the support of the automation .

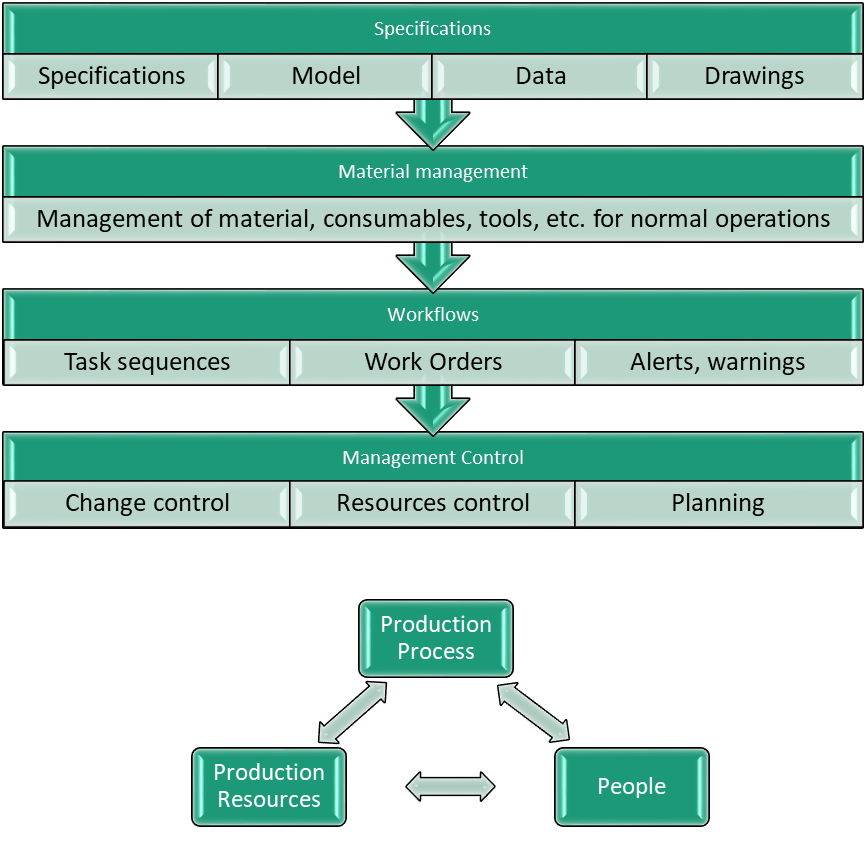

Any Shipyard needs a powerful set of tools that manage and control all preventive, predictive and corrective production processes, establishing a unified processes for all production tasks with the greatest simplicity as possible.

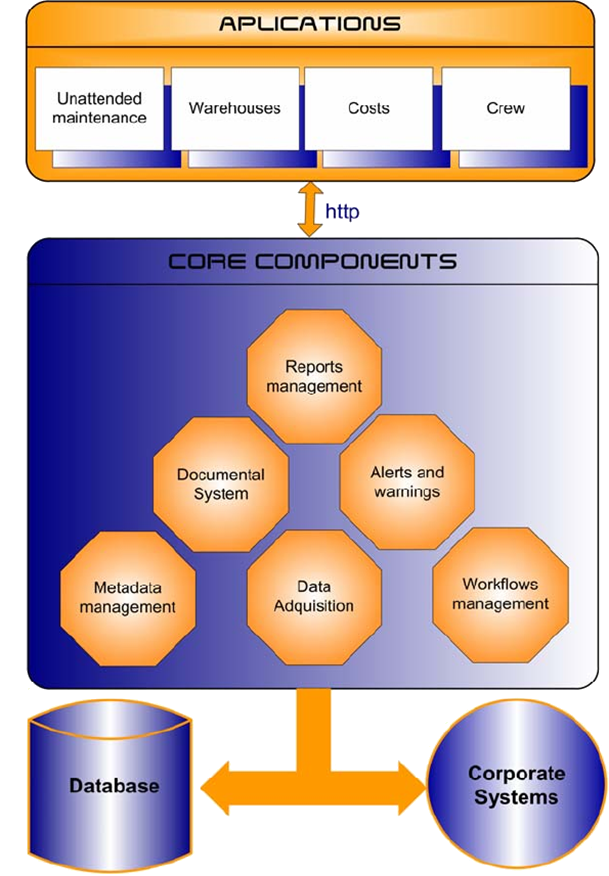

We will sketch in the present post an applications for supporting the procurement, planning, project management, shipyard management and fleet management processes.

Benefits of a Production Management System

- It establishes uniform mechanisms in terms of methodologies, execution and information.

- Absolute traceability of all operations carried out is maintained.

- Integrate all the necessary documentation (plans, certificates, specifications, …).

- It considerably reduces the cost attributable to maintenance management.

Technology

- 100% Java

- Web base

- PostgreSQL

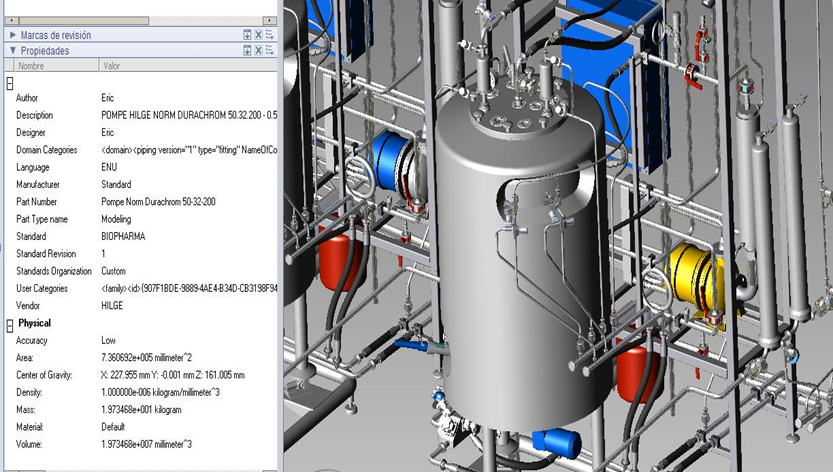

- Extract data from current Shipbuilding CAD Databases or from 3D models.

Some of the Must have are:

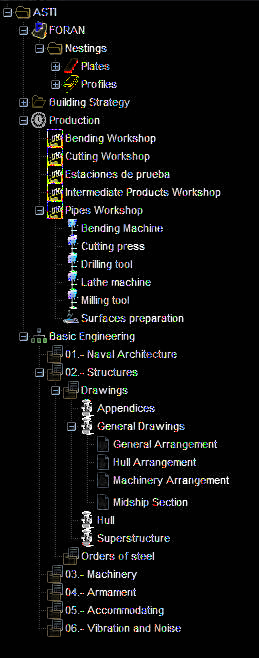

User Defined Hierarchical Tree Nodes

Control Access:

- READING

- WRITING and

- MODIFICATION CONTROL

Encrypted Information

Exensive use of METADATA

- Estandard XML

- User defined

- Access external Metadata

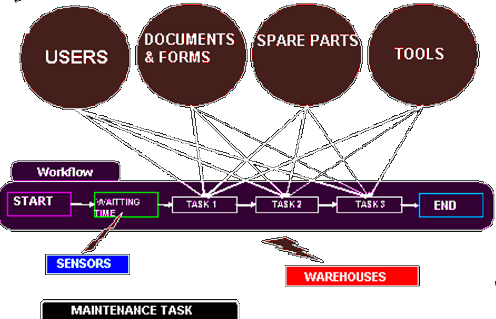

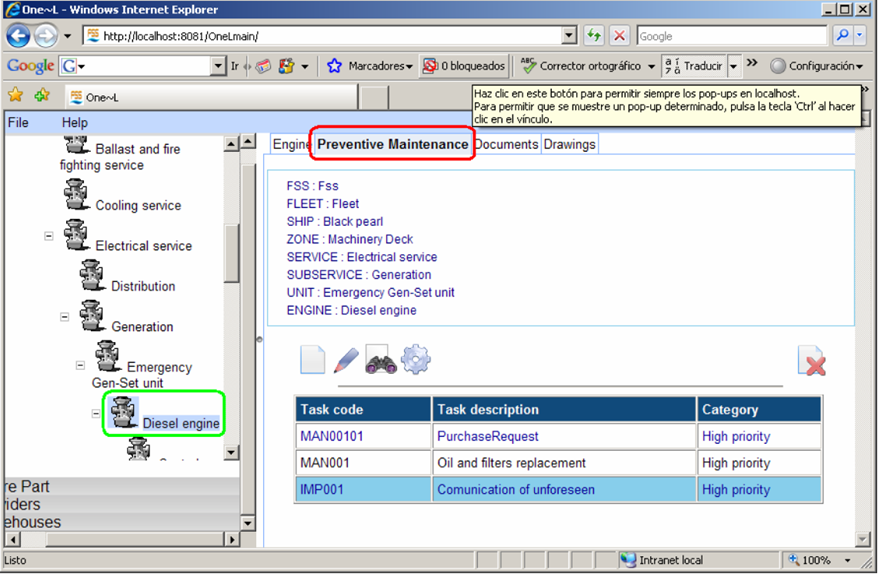

Preventive, predictive and corrective tasks

- Definition of unlimited preventive maintenance tasks for each of the nodes of the system (parts to replace, tools, …).

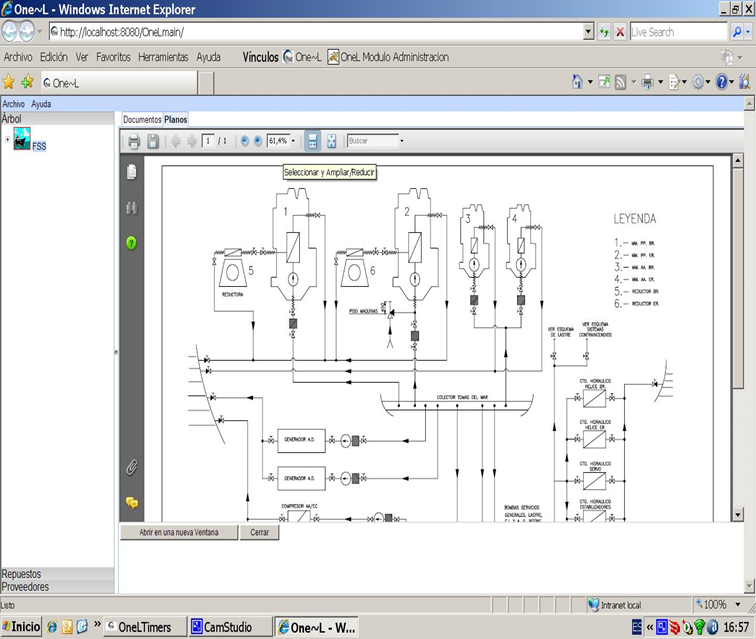

- All the necessary documents are integrated (drawings, diagrams, sequences, deliverables, …).

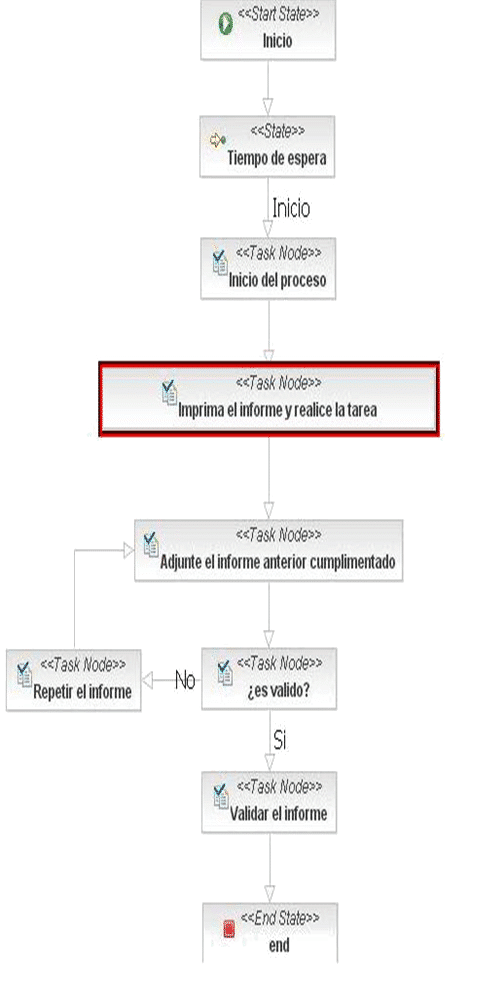

- Definition of work orders through workflows.

Document Management

3D Viewer

Automatic control of building process

Traceability of all operations in progress and carried out throughout the entire life cycle.

Flexible report generation.

Definition of “unattended” building processes

User defined REPORTS

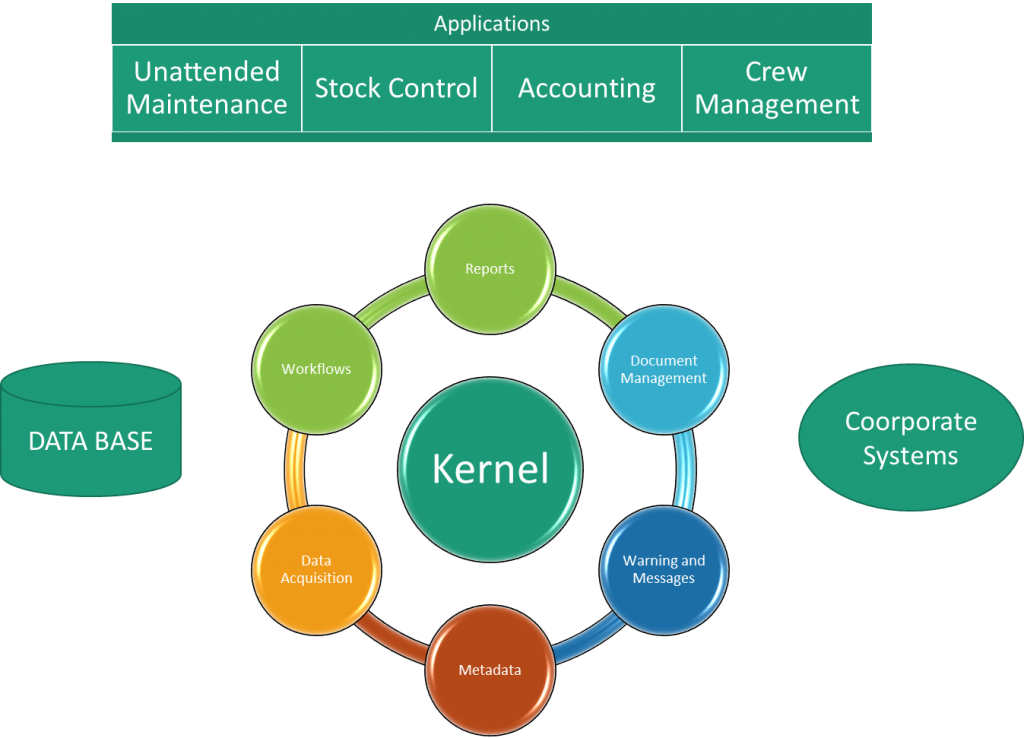

Architecture

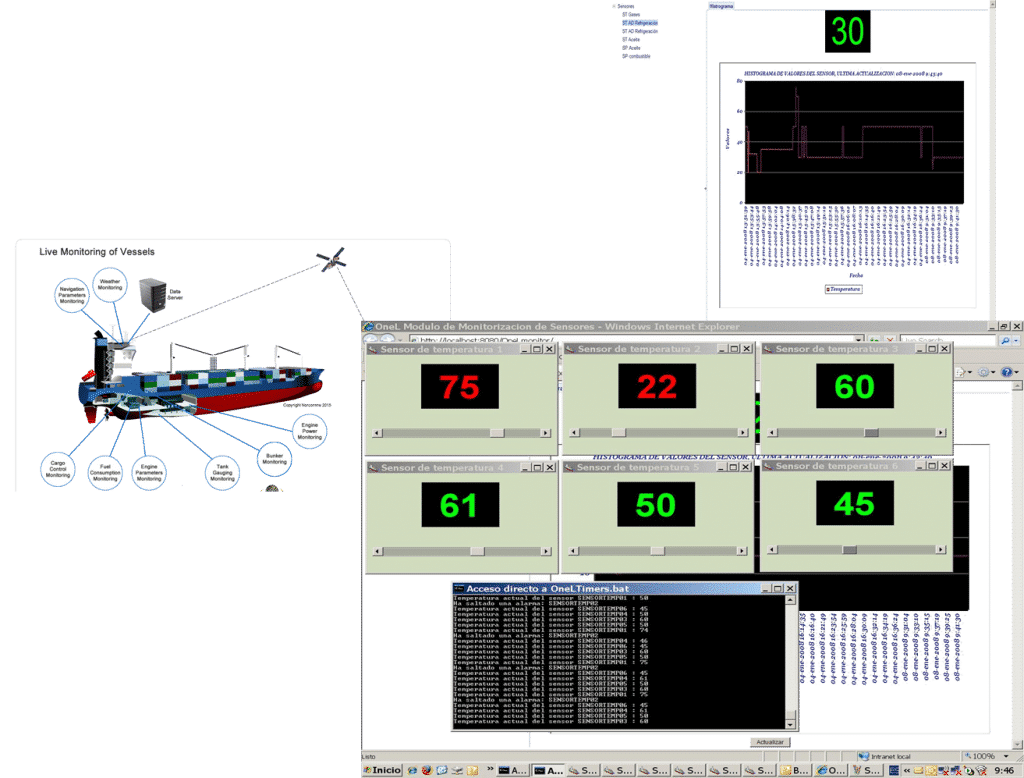

Sensorizations

Real time control

Continuous Registration

Alarms

Export to Excel files

Information treatment

Automatic control of the building process

Development and integration of interfaces for data acquisition.

The “demon” workflows verify in real time the data received and are responsible for executing the programmed actions in case of alarms.

SOFTWARE, CONSULTING & SERVICES

- Onboard Installation

- Customization

- Installation and setup completely carried out by our specialist

- On demand improvements and

- New developments