The maintenance of the fleet is of key importance in the business of shipping due to the increasing complexity of the equipment installed ships, the complex mechanical components, maintenance sercices, electrical connections, electronics, automation, fluids, software, …, and lack of onboard maintenance services. Therefore its maintenance has become of the aftermost important tasks and consequently, had been increased the efforts and expenses of the consignataries companies.

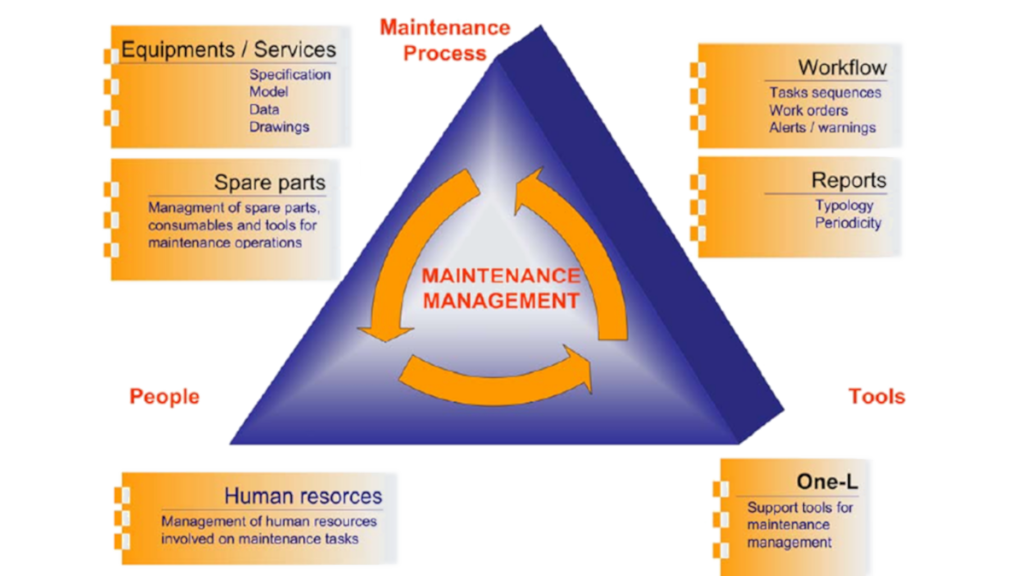

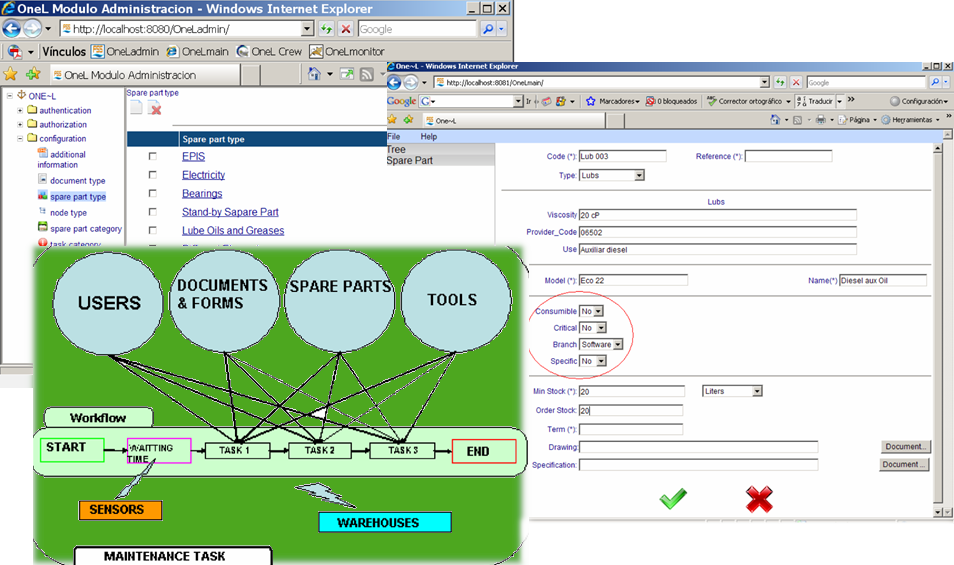

The management of maintenance must begin with the definition of the process in which are involved a large amounts of equipment, services, spare parts, documentation, workflows, reports, orders, teams… The management of all these components requires a lot of coordination and automation in order to maximize it efficiency and have enough time for planning and maximize the sailing of the fleet..

Any Fleet needs a powerful set of tools that manage and control all preventive, predictive and corrective maintenance processes. It establishes a methodology to unified the processes of all maintenance tasks on the fleet, with great simplicity.

In the present post we will preview a Fleet Management System:

Benefits of a Fleet Management Tool

Some of the most relevant are:

- Standardization of mechanisms and methodologies of processes and control.

- Traceability of all transactions.

- Integration of all the necessary documentation (drawings, certificates, specifications).

- Ability to receive and send all relevant onboard information in real time.

- Reduce dramatically the costs of management and maintenance.

- Increase the quality of all maintenance processes.

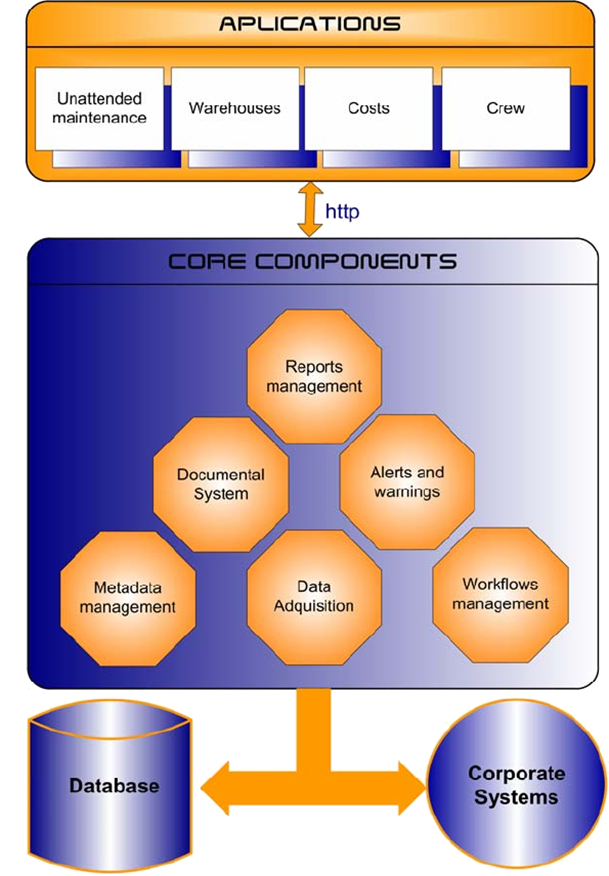

Technology considered

A typical set of technologies would be:

- Web base

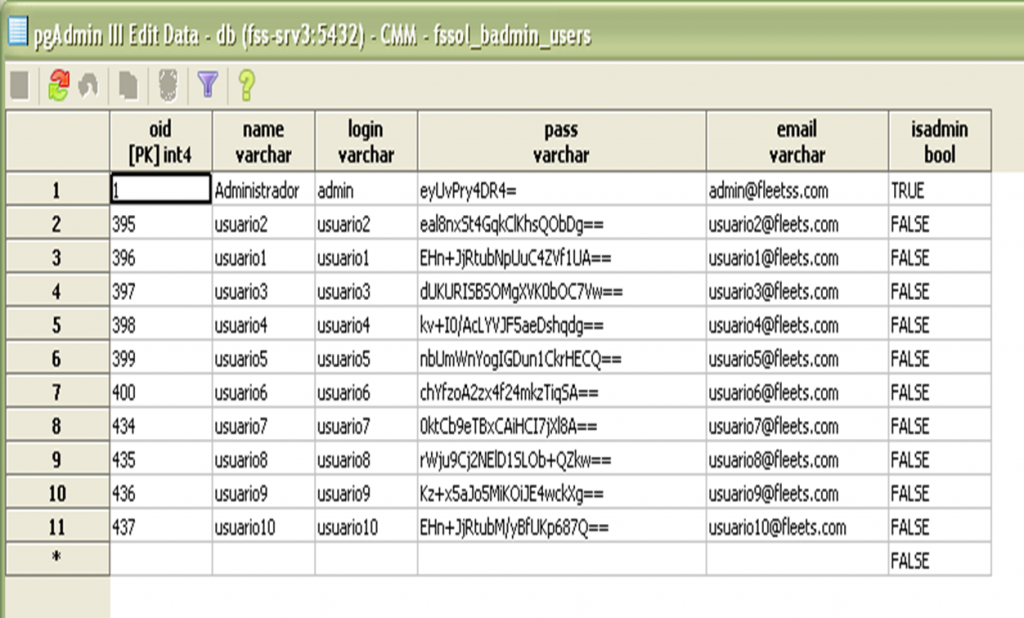

- Store the data in databases like PostgreSQL, Maria DB, Oracle, etc.

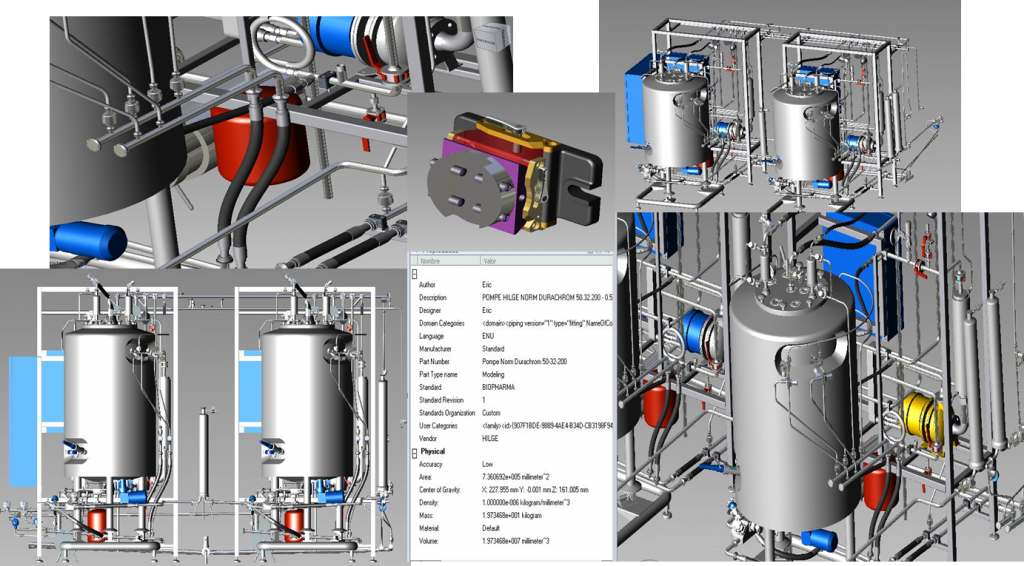

- The convenience to extract the data directly from a 3D product model or most modern approach, its “digital twin”.

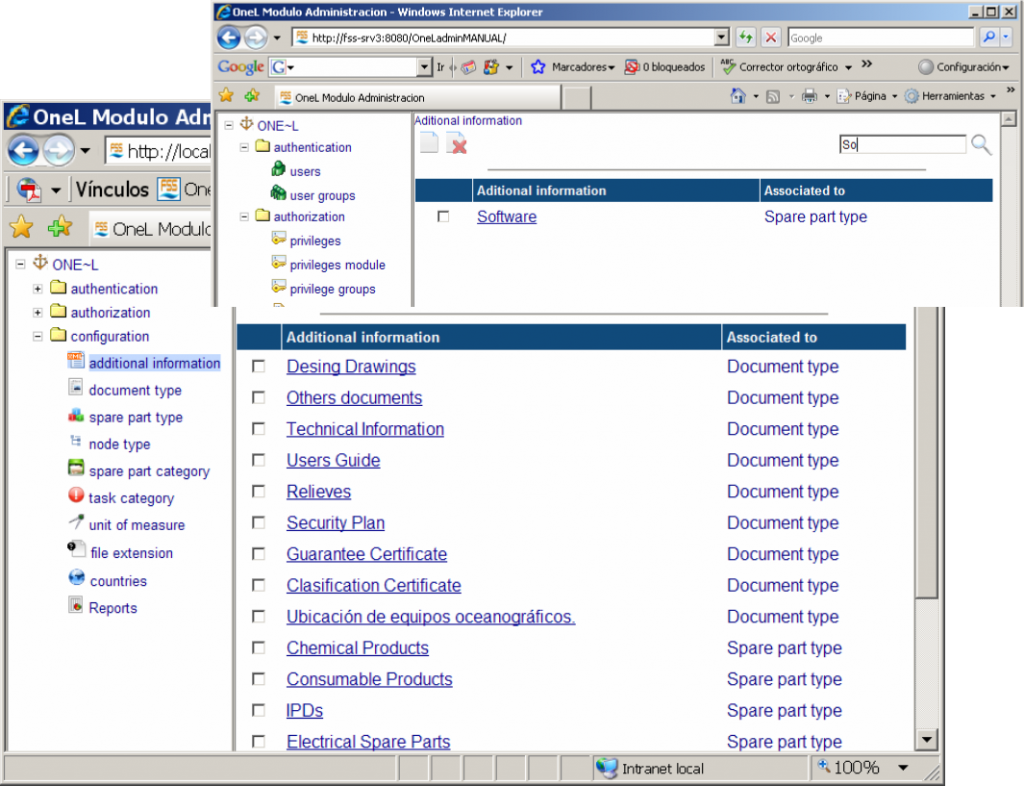

- It should be easily configurable.

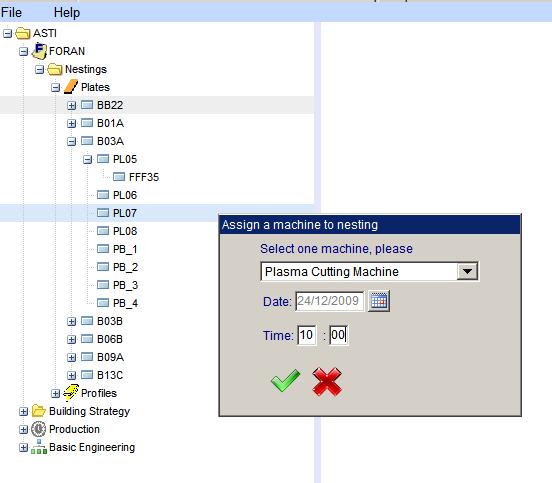

Application Architecture

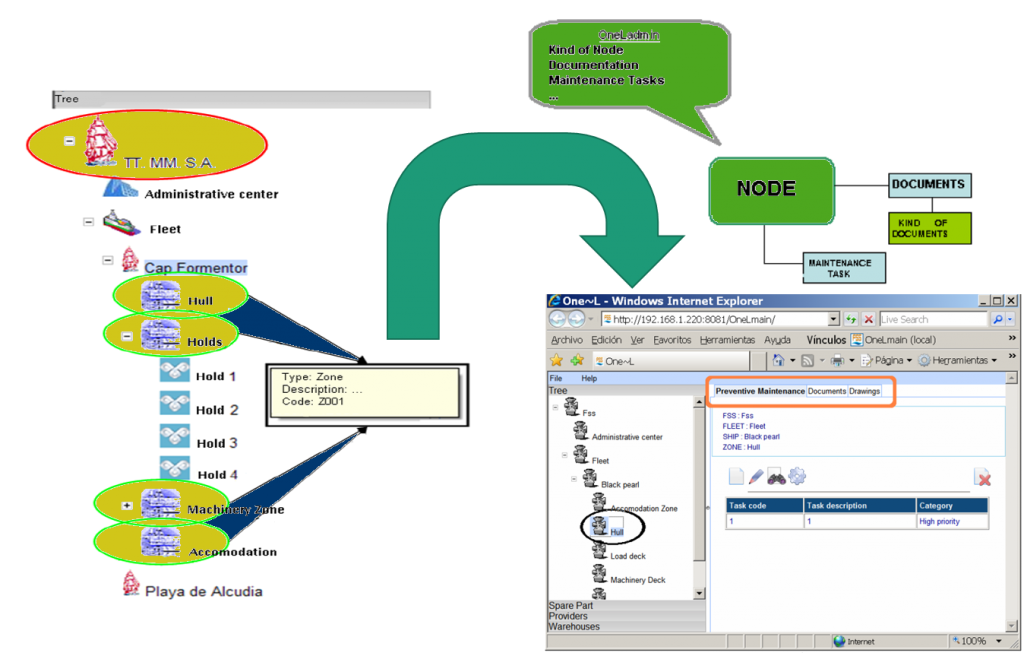

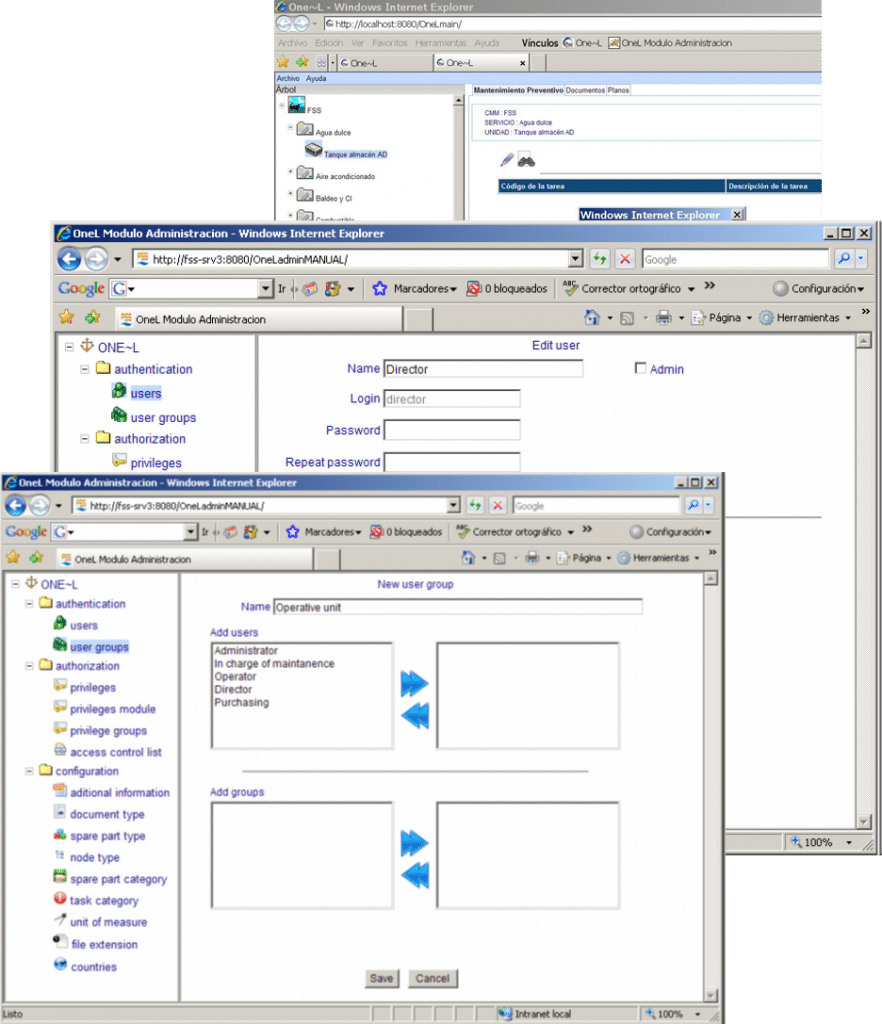

Hierarchy Tree Node

- Root node (Ship/Shipyard/Warehouse).

- Production Plants / Administrative Centers.

- Sections / production lines.

- Warehouses.

- Zones.

- Areas.

- Services.

- Subservices.

- Units.

- Teams.

- Systems.

- Subsystems.

- Mechanisms.

- Elements

Full control access and security

Reading, writing, modification control, users, group of users, encripted information,

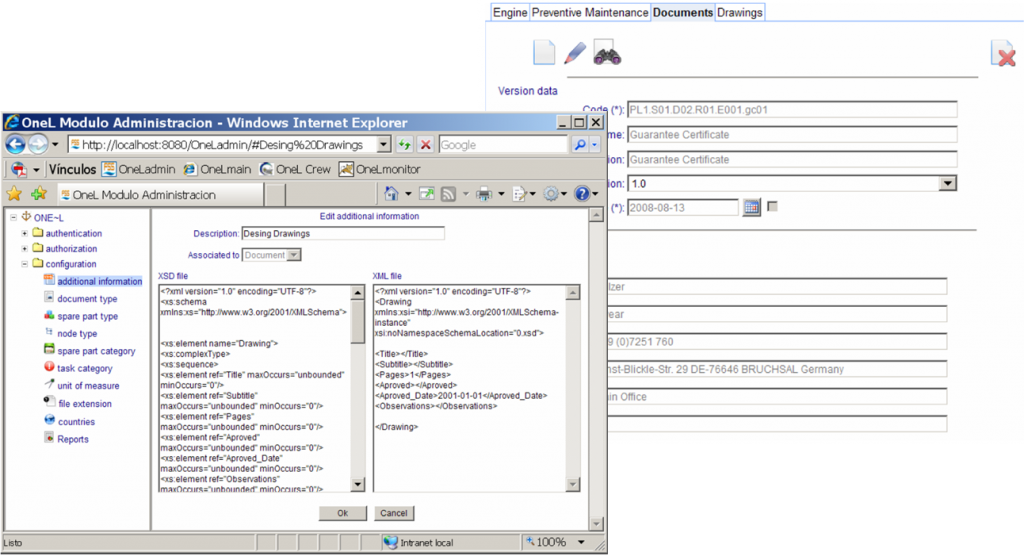

Easy access to the Metadata

It is highly convenient to allow the definition of user’s data by means of the Standard XML protocols and it must be easy to access this external Metadata from third party application and report tools.

Preventive, predictive and corrective maintenance processes

In order to achive the functionalities of been Preventive, predictive and corrective maintenance within the maintenance processes the following requirement must be achieve:

- Definition of unlimited preventive maintenance tasks for each of the nodes of the system (parts to replace, tools, …).

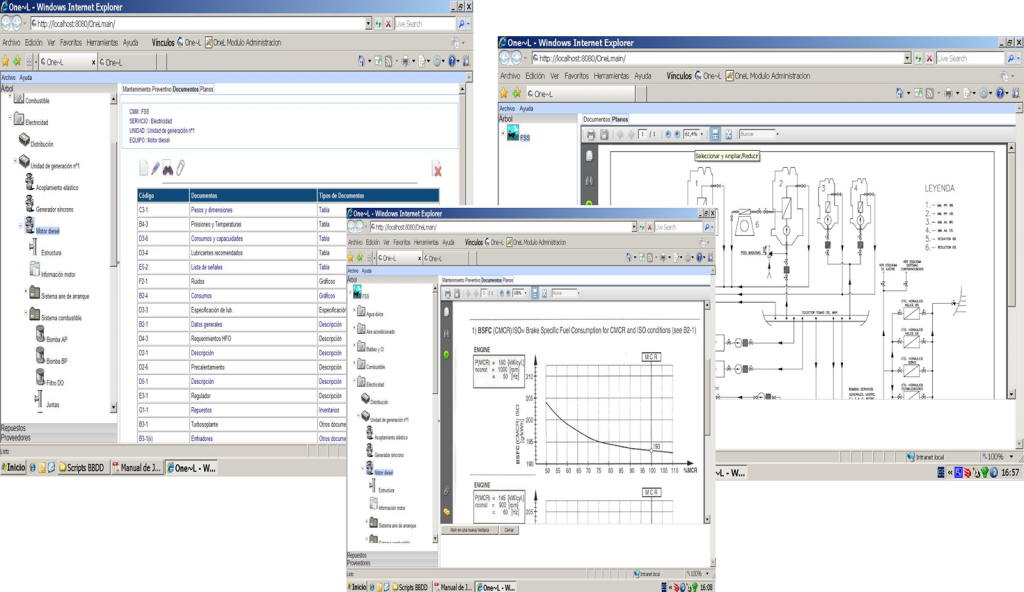

- All the necessary documents are integrated (drawings, diagrams, sequences, deliverables, …).

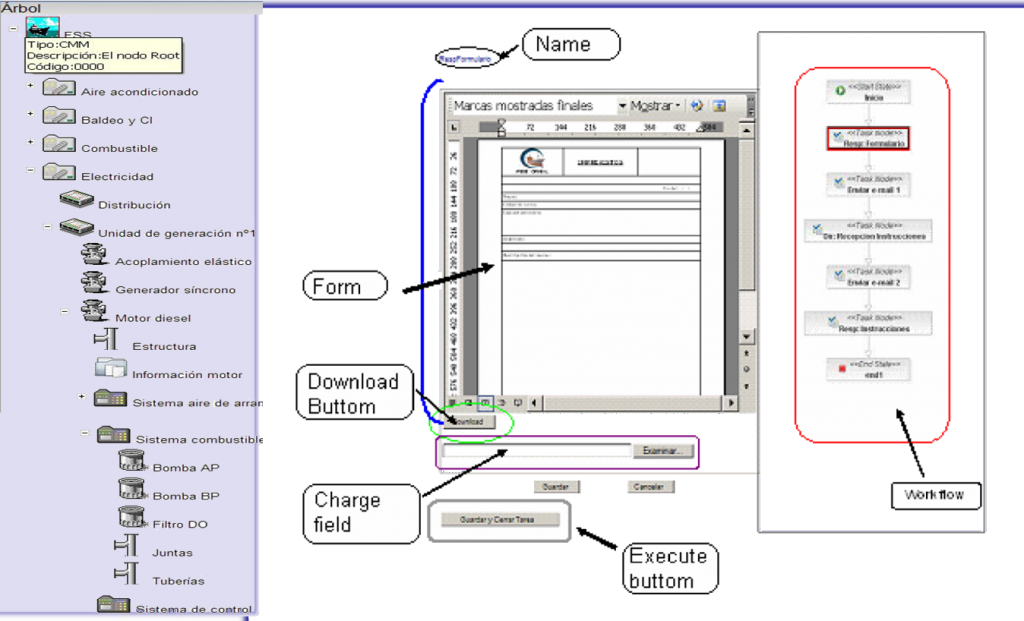

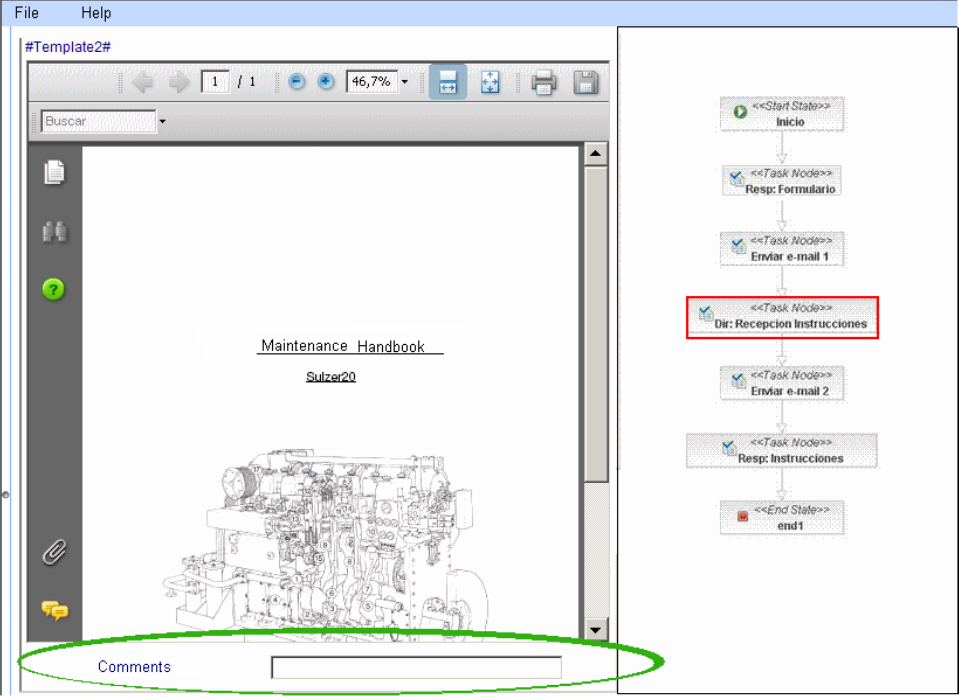

- Definition of work orders through workflows

System Nodes & User Defined Workflows & Associated Documentation

Document Management

3D Viewer

Tasks

There must be a task panel where the systems shall tells us which node has been created the maintenance tasks (Route), the workflow is the engine of this task, the name of the step we are going to make and the version of the workflow we are running. Each list of the tasks shall be:

- Traceably of all operations in progress and carried out throughout the entire life cycle.

- Flexible report generation.

- “unattended” or “automatic” for the maintenance processes.

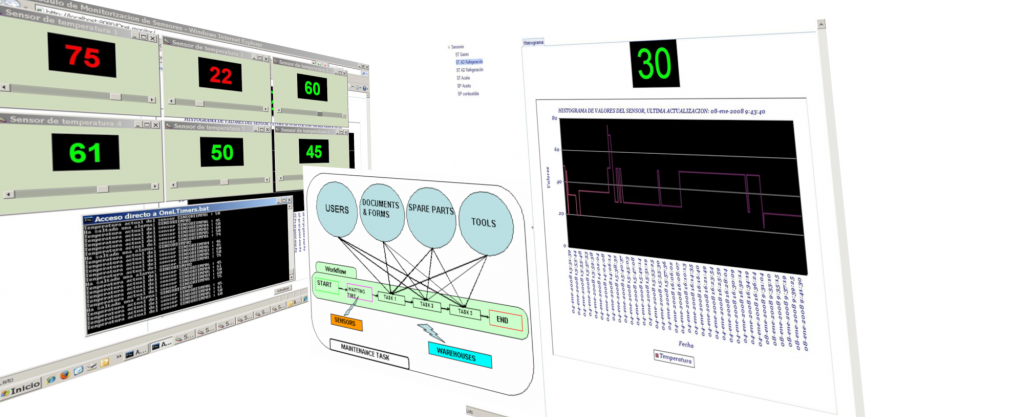

Sensorizations

- Real time control.

- Continuous Registration

- Alarms

- Export files (Excel…)

- Information treatment

- integration of interfaces for data acquisition.

- A “demon” for the workflows shall verify in real time all the data received and shall be responsible for executing the programmed actions in case of activate a trigger or an alarms.

Automatic Tasks

- Send e-mails.

- Stock Checks.

- Stock Reservations.

- Stock Discount.

- Timeouts.

- Checking sensors.

- Submitting reports via e-mail.

- These are customizable tasks based on the parameterizaton and related with the workflow.

SOFTWARE, CONSULTING & SERVICES

- Onboard Installation

- Customization

- Installation and setup completely carried out by our specialist

- On demand improvements and new developments